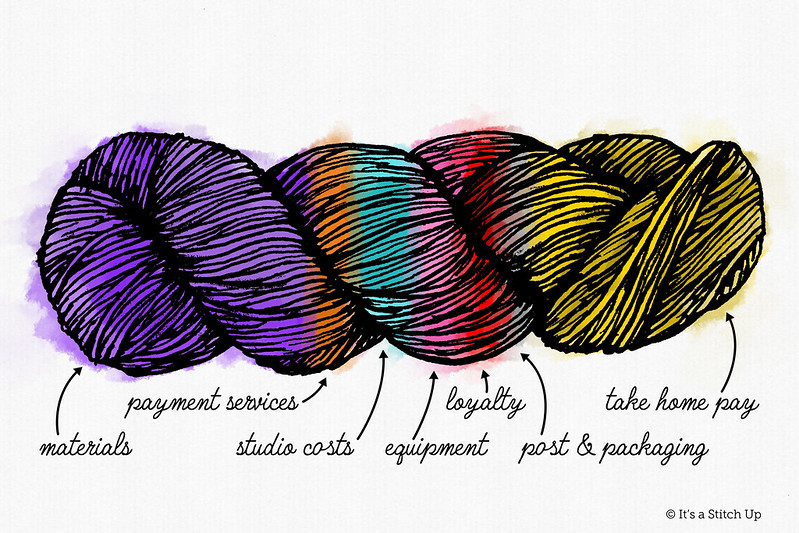

We know that hand-dyed yarn is not cheap and for most of us it’s a special treat. Ever wondered why it costs what it does? We thought you might be curious to see exactly where your money goes.

We believe in being transparent about what makes up our costs. We’ve based our calculations on skeins sold on our website. If we crunched the numbers for yarn sold through our LYS stockists, at an event or from our Etsy store, the percentages would look quite different.

Materials costs – around 38%

It should be reassuring that raw materials make up the biggest chunk of the costs of a skein. These costs include the bare yarn, dyes and other chemicals used in the dyeing process. We’ve also factored in the printed bands and labels – the complete physical product.

The yarn we use is relatively expensive – costing more to us at wholesale than some commercial yarn costs to buy at retail. However, we are happy to pay more for superb, consistent quality and commitments from our suppliers to ethical, sustainable sourcing.

Unfortunately, the cost of yarn and fleece has increased noticeably since our last price increase 18 months ago, largely due to the economic impact of Brexit, and this is the main reason why we’ve had to review our prices now.

Payment services – around 6%

Every time we receive an order, our payment providers take their cut. Using PayPal, this works out at about £1 per skein, but the amount varies depending on the transaction currency, country location of the customer and size of the order. Sometimes it feels frustrating to lose this money upfront, but it’s important to remember that without payment services, we wouldn’t have a business at all. PayPal provides us with the tools to build secure e-commerce into our website with minimal web development. It also has features like automated subscriptions which we rely on for our yarn clubs.

Studio costs – around 9%

We do all our yarn dyeing in a dedicated studio space. Rent is a fixed cost, so it’s hard to quantify the studio cost per skein – it depends on how many skeins we’ve managed to dye each month! These costs also include power and our travel to and from the studio.

We have moved studio twice in the last two years, having lost our previous spaces to redevelopment. The pressure for housing in the capital means that industrial areas, like the one where our current studio is situated, are disappearing. We feel very lucky to have an affordable workspace! The studio made it possible for us to scale up and dye much larger batches.

Equipment costs – around 7%

Again, this is a tricky one to quantify per skein, so we’ve factored our equipment spending throughout the year divided by the approximate number of skeins we’ve dyed.

This segment includes buying and maintaining the equipment we use in the studio (industrial catering and laboratory equipment) and beyond (e.g. IT & photography equipment, software and storage furniture). I was reluctant to invest in expensive kit when I first started the business, making do with what I had. Over time I have come to realise that the right equipment makes the job safer, faster and easier. I am eager to invest in tools that last.

Loyalty programme – around 6%

We launched our Yarn Loyalty Card just over two years ago as a way to say thank you to the customers that support us time and again. Like most small businesses, we felt incredible pressure to offer discount codes, introductory offers, Black Friday deals and January sales. But, these encourage impulse buying, over-consumption and artificial pricing are at odds with our business values, so we decided to do something different.

This is the amount we spend running the loyalty programme, which goes straight back to customers in the form of the bonus yarn they earn collecting tokens.

Postage & packaging – around 4%

Even though we charge for shipping, this amount doesn’t cover our shipping costs. The main reason is that environmentally-friendly packaging materials are expensive! As a tiny business, we often find that we don’t qualify for bulk discounts that larger retailers get on things like envelopes and tape. We have to factor in those costs when we’re pricing our goods, but it means that we’re able to ship larger orders for free within the UK because they’re more efficient on packaging materials, and we can pass that saving onto you.

Take-home pay – around 30%

This part effectively pays my wages, not only for the time spent dyeing, but the many and varied activities that are running the business. Here are just a few:

- Labelling, photographing and listing new colours on the website, social media and newsletter

- Responding to your messages about everything from choosing a gift for a loved one to tracking down a missing order

- Ordering supplies and keeping on top of our accounts

- Researching and testing out new yarns and fibre to develop new lines

- Designing print materials and building new website features

- Writing this post!

So, was that what you expected? We hope you agree that our yarn is fairly priced and and that there’s a lot going into every skein. We would love to see how commercial yarn compares!

Hi, I thought I saw something on your page about acrylic yarn and now I can’t find it :( Although I wrote my book six years ago, it’s still selling and I give talks to various groups, now on Zoom and Streamyard.

I need to be clear about acrylic yarn. I thought it was rubbish and is full of microbeads which is bad for the plant – I don’t use it myself any more. However, one of the yarn sellers tells me that there are no microbeads of plastic in their acrylic. So I asked what it is made of. I’m still waiting for a response.

In my talks, I want to be clear about what I’m telling people and trying to encourage them to use natural yarns. Can you help please? Or point me to your message that says about acrylic yarns.

Many thanks.

Elizabeth Caush

Hi Elizabeth – here are a couple of posts that might be helpful:

https://itsastitchup.co.uk/ethics-sustainability/we-need-to-talk-about-nylon/

https://itsastitchup.co.uk/ethics-sustainability/eco-conscious-yarn-on-a-budget-part-1-is-there-a-case-for-cheap-acrylic/